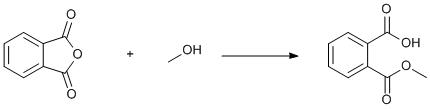

Methanolysis of phthalic anhydride

SyntheticPage 428

DOI:

Submitted: July 1, 2010, published: July 5, 2010

Authors

Christopher Cooksey (rsc@chriscooksey.demon.co.uk)

A contribution from

Chemicals

methanol

Procedure

Author Comments

A subsequent perusal of the literature reveals a much simpler procedure, 0.5 h reflux and no toluene: "Under a nitrogen atmosphere, a mixture of 75.0 grams (0.506 mole) of phthalic anhydride in 120.0 grams (3.75 moles) of methanol was stirred and heated under reflux for 30 minutes. During this time a complete solution was attained. The reaction mixture was concentrated under reduced pressure to a residual oil. The oil was placed in a refrigerator where it solidified to yield when dried, 93.0 grams of phthalic acid, mono-methyl ester; m.p. 80-81.5 ºC." in quantitative yield.

Chang Jun H, Baum J S, US 4892578 (9 Jan 1990)Data

Lead Reference

E L Eliel, A W Burgstahler, J Amer Chem Soc, 1949, 71, 2251-2252. doi: 10.1021/ja01174a509

Other References

Keywords

addition, alcohols, carboxylic acids, esters, nucleophilic