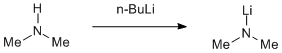

Deprotonation of a secondary amine

SyntheticPage 422

DOI:

Submitted: June 1, 2010, published: June 7, 2010

Authors

Alan Faulkner (alan.faulkner@warwick.ac.uk)

A contribution from

Chemicals

n-butyllithium 2.5 M in hexanes (Aldrich)

Dimethylamine (Aldrich, 295280 in surepak cylinder)

Pentane (Distilled from potassium and degassed)

Procedure

A dry one-neck 500 ml RBF with a PTFE stopcock sidearm, containing a very large egg-shaped magnetic follower and a fresh SubaSeal fitted to the joint, was set up as detailed below. Using Schlenk techniques under argon, n-butyllithium (100 ml 2.5 M in hexanes) was added from a measuring vessel (volume too large to be handled safely by syringe) followed by dry pentane (200 ml). The solution was cooled to -40°C in an acetone /dry ice bath with stirring and dimethylamine gas bubbled through the solution such that the internal reaction temperature was maintained between -29°C and -26°C. A white solid precipitated immediately. After around 1 h of cautious gas addition (regulating flow and sometimes switching off altogether) it was found that gas addition no longer led to an exotherm and no additional precipitation was detected. The system was allowed to warm to ambient temperature with gentle stirring under argon. The white precipitate was left to settle for some time and then isolated by cannula filtration, washed with pentane (2 x 50 ml), filtered again and dried in vacuo. Yield 12.08g (95 %)

Author Comments

- Dimethylamine is a gas but is also available as a solution in THF. We did not want to contaminate the product with ethers so we opted for the gas cylinder. This is also a more economic method. The Aldrich website suggests the use of a Stainless steel hose adapter Z146838 or stainless steel body mini gas regulator Z513547, but since we were not interested in regulating the pressure (only the flowrate) we opted for a simple brass needle valve. The SurePak cylinder comes with a valve on top of course but this is not good enough to regulate the flow properly and we would not recommend settling for this alone as this is the main way of regulating the internal temperature of the reaction. The outlet of the needle valve was connected to Portex tubing (PVC would do) and then to a long 16 gauge needle. This went through the SubaSeal into the reaction vessel. This is a convenient setup as you can either bubble the gas through or let it pass over the top. Also, when stopping the flow of gas you can prevent suck-back by pulling the needle out of the solution. In our opinion, this obviates the need for a suck-back trap, but do follow your own local rules or supervisor's advice.

- The Suba is also fitted with a vent needle connected to a nitrogen bubbler to make pressurisation of the system impossible and also so that the outlet gas can be diluted. You may want to pass this outlet gas through a scrubber to remove the amine, but we found that if diluted sufficiently it did not cause problems in our fumehood system.

- We also used a simple food-grade thermocouple to measure the temperature of the reaction mixture as this has a quite stiff but narrow probe which is convenient for going through a Suba.

- The various objects sticking out of the Suba were stabilised as appropriate with clamps.

- The PTFE (rotaflo) sidearm on the RBF was used mainly to get the vessel under argon in the first place but was closed during the reaction as gas was vented via the exit needle and bubbler. At the end of the gas addition stage, this stopcock allows you use Schlenk techniques in the isolation stage.

- Approximately two equivalents of dimethylamine were added during the course of the reaction based on the change of mass measured for the cylinder.

- The key thing to remember is that if you want the reaction to stop, just turn off the limiting reagent - the dimethylamine gas.

- Filtration of the product is considerably easier if solid is left to settle out over a period of half hour.

- The resulting product decomposes rapidly in air so was stored in a glovebox.

- Note that as an insoluble and very air-sensitive material it was not characterised other than through use in the synthesis of tetrakis(dimethylamido)zirconium.

- Note that this synthesis could also be conducted under dinitrogen rather than argon.

Data

Lead Reference

Other References

Keywords

amides, amines, Lithiation, organometallics